| Manufacturer |

| |

|

-------------------------------------

|

|

Tech Notes (1 of 3!)

This section provides you the opportunity to

share your favorite diagnosis or interesting waveform capture with other AES customers.

We welcome you to

submit your favorite experience captured with your

scope or the AES Wave!

Catch a Wave!

Tech Note 010:Testing Nissan Ignition

Submitted by Tom Roberts

I often see questions over e-mail about testing

Nissan distributor-power transistor ignition so I thought a post on this subject was in

order. There are a lot of these on the road and for the most part it is a dependable

system, but age takes its’ toll. I thought I would share with you the techniques I

use to zero in on the problem along with some helpful pictures.

The system is rather simple, with few components,

and is best tested with the DSO. Basically, the trail starts at the distributor, which

houses the optical crank angle sensor. This sensor is an LED and collector, separated by a

rotating disc with many slots. The signal strategy is, as with many optical distributors,

a high and low resolution signal pair. These signals are digital square wave signals. The

high resolution signal has a voltage transition for each degree of crankshaft rotation, so

it is called the 1 degree signal. Each voltage transition high and each low represents one

degree. The low resolution signal has one signal cycle (positive and negative transition)

for each cylinder. So, on a four cylinder this would be the 180 degree signal, since a

cylinder is up every 180 degrees, and on a six cylinder it would be the 120 degree signal.

Here is an example of a good CAS 180 and 1 degree signal relationship:

And here is an example of a 120 and 1 degree

relationship:

The low resolution signal usually has a wider sync

pulse, carbureted or fuel injected. Here is a capture of the wider sync slot in a 120

degree signal:

These signals are processed by the ECU along with

other inputs for spark timing. The ECU then sends out a command signal to the power

transistor, which controls the coil primary. Here is a capture of the relationship between

the CAS 180 degree signal and the power transistor command. Here also the wider sync

pulses can be seen in the 180 degree signal.

Here is an example of the relationship between the

power transistor command and coil primary:

And this is an example of what happens to the power

transistor command when there is a 180 degree signal failure:

Here is an unusual 180 degree CAS failure which

became a mirror of the 1 degree signal:

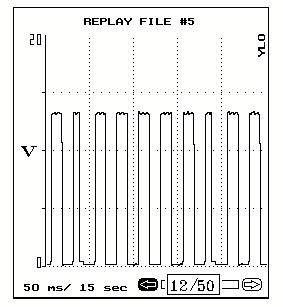

And here is an example of a high rpm CAS 1 degree

signal failure. This one had a symptom which mimicked valve float. The symptom could only

be duplicated at high rpm. The engine would begin to backfire in the intake and bog down,

as the spark command failed due to the 1 degree signal failure.

The power transistor command looks quite different

when it is not interacting with the transistor. Here is a capture disconnected from the

transistor:

This is important to note since it can indicate a

failed transistor. Here is an example of a failed transistor from an 8 plug Z24 pickup:

Keep in mind that the eight plug systems do not

trigger the exhaust side ignition under certain load and rpm ranges. That’s why

secondary ignition problems on the intake side usually show up under load. So don’t

be surprised to see the power transistor command disappear under these conditions.

To solve ignition problems reliably on these, all

you need is some basic knowledge of how the system works, some diagrams, your scope, and

your instincts. Just follow the electronic trail to the source of the failure. This works

in almost all cases, but you can’t win ‘em all. Case in point, an ‘88

Pathfinder with a very weak spark which would not start. Good primary pattern could be

seen and the coil wire was OK. Conclusion, bad coil. WRONG. A failed power transistor was

the culprit. Here’s the pic:

Now when I encounter weak spark on one of these,

before I condemn the coil, I try to do a primary current check as well as primary trigger.

Here is an example of a Maxima no-start due to weak spark, showing good primary trigger

and current:

A new coil is all that was needed.

I hope it has been helpful to share some of this

with all of you. I welcome any additional comments or techniques. I don’t mean to

make this seem simplistic. I would be the first to admit that some of these can drive you

nuts. Duplicating and capturing the failure is sometimes quite difficult, and seemingly

unexplainable things do occur. But I have found that this strategy works well for me in

almost all cases. I have learned so much from iATN, I thought I would just try in some

small way to contribute. Even though this is probably old news to most of you, I’m

sure some can benefit.

Tom Roberts

|

|

Back to Top

|

|

| Tech Note 009: Using

an Amp Probe with your DSO

Submitted by Bill Lakow

What not to Test with an Amp Probe

Most vehicle PCM input signals do not produce enough current to test with a

current probe, it is best to view the voltage trace of those signals.

Test These Instead

The engine management signals that we want to test with the milliamp probe

are the output signals that control solenoids, motors, and relays.

The milliamp probe can be used for testing fuel

pumps and other low current electric motors. Ignition coil current can also be tested with

the lab scope.

Most dual-channel scopes will allow you to view

ignition coil current and secondary voltage at the same time with the help of an amp

probe.

If you have the Interro PDA allow you can

view these signales by using the Scope Channel in the Engine Test menu.

Figure 1 below, is a new

fuel pump voltage and amperage trace on a GM CMFI system. This system requires a minimum

of 8.5 amps.

Figure 2 below, voltage signal is

good and the amperage signal is faulty. The fuel pump motor has an open circuit and the

vehicle had a loss of power.

Figure 3 below,

displays secondary ignition and coil current. This screen captured the crossfiring in the

secondary and verified that the coil triggering was not at fault.

The milliamp current probe allows quick and accurate

non-intrusive testing.

Test good to know good. Test good current

signals and note their shapes and amplitude and then make them "bad" and note

the changes in the signal. |

Related AES Links:

• Low Current Probes

• Interro PDA |

Back to Top

|

|

| Tech Note 008: Injector

Drivers

Submitted by Tom Roberts

I thought I would post this short article on

injector drives so those of you who are new to DSO technique and any others interested

might benefit from my relatively limited knowledge and open up some feedback and

discussion which would enrich all of us. Observing injector waveforms for the first time

can be somewhat confusing. Hopefully this information will help to make things clearer and

speed things up on the road to proper injector diagnosis.

Injector drive types can be divided into three

categories:

1. Saturation

2. Peak and hold

3. Pulse width modulated

In each category there are two styles: positive and negative control.

All electronic injectors I know of fall into these categories.

Saturation (or conventional) Drivers

Since this type has no current limit feature, injectors using this method

usually have higher resistance or added circuit resistance. When voltage is supplied to

the injector circuit and the driver provides the ground to flow current through the coil

and open the injector, it is negatively controlled. Here is an example:

Most of the drivers in this category are port fuel

injected.

This, however, is a Nissan Sentra TBI. The

injector is low resistance but there is a resistor in the circuit to reduce current flow.

When the ground is supplied to the injector and the

driver provides the power the picture is a little different:

To acquire the pattern the scope must be on the

control side of the injector.

Peak and Hold Driver

This type of driver peaks current to open the injector and then limits

current to only what is needed to hold it open. Here is an example of a negatively

controlled peak and hold driver:

Here is an example of a positively controlled

driver:

Most TBI injectors fall into this category. When

measuring pulse width on these, measure from the beginning of the peak section to the end

of the hold section as the cursors show.

Pulse Width Modulated

This type of driver peaks to open the injector but has a different current

limiting strategy. Instead of a steady hold section, it turns the current on and off very

rapidly or modulates it. Here is an example of a negatively controlled pulse width

modulated driver:

Below is a positively controlled pulse width

modulated driver:

Here, you should also measure pulse width from the

beginning of the peak section to the end of the pulse modulation section as the cursors

show.

There are some interesting combinations too. Honda

civic dual TBI units use an auxiliary injector which has a saturation driver and a main

injector that uses a pulse width modulated driver. The names seem backwards though, for

the auxiliary injector is used all the time and the main injector comes in under light to

heavy load conditions. It is not active at idle. Here is an example of both injectors

under light load cruise. The top is the Auxiliary and the bottom is the main:

Here is the same under acceleration. Note the added

quirk of a current limit hump in the peak section of the main driver.

Common Failures

I thought I would also include a few common failures that can be recognized

from the DSO trace. GM TBI peak and hold drivers often fail to control the hold section.

This is usually a progressive failure. In the early stages the hold section gets wavy

under acceleration. The owner may not notice any symptoms at all. Later if the driver

degrades more, symptoms vary from rough idle and hesitation to extreme roughness and black

smoke. I have noticed that if one driver in a dual TBI unit is blown and the other is not,

symptoms seem to be worse.

Below is an example of a badly blown driver:

There are varying opinions about the seriousness of

this failure. I have found that the symptoms are inconsistent with the seriousness of the

pattern degradation. In this example, the symptoms were serious.

Unbalanced injection and resulting lean misfire with

ECM compensating for resulting O2, creating a rich condition at times. Others I have seen

in similar shape have no symptoms. Basically I am saying not to blame symptoms on this

failure alone. What I do if I suspect that this is a possible cause is to install a .1mfd

capacitor (Radio Shack # 272-1053) across the injector. This will clear up the pattern. If

the symptoms are still there then move on. If that fixes it, then you just have to decide

to leave it at that or replace the ECM. Often rebuilt ECM's have similarly blown drivers

in them already.

Shorted GM Multec injectors are common as well. The

give away in the pattern is a high ground offset (the distance from the lowest point to

ground), and low comparative inductive kick (spike when injector shuts off). Ground offset

should be generally within 800mv of ground. The spike varies by application so compare

this to others. Some ECMs will shut down when injector current gets too high to keep from

going up in smoke.

Below are a couple of examples of shorted injectors

with saturation drivers:

Below is a Quad four example of a shorted injector

with a peak and hold driver. Here add to ground offset and inductive kick problems the

time of the peak section before the ECM begins current limit hold section. Also note the

oscillations in the hold section:

And the good driver for comparison:

Remember that when one shorted injector steals the

current from others in parallel the good injectors may be the ones misfiring.

Another common failure cannot be identified with a

scope. Failed injector patterns look identical to good ones, resistance and current is the

same. This failure is most common on Chrysler 2.2 and 2.5 TBI. Symptoms are stalling at

idle, hesitation aggravated when cold usually. You will see the injector spray sputter or

stop during the event. The engine can be made to stall lean by squeezing the return line

to raise fuel pressure. A new injector clears this up.

I hope this is of some help to a few of you who

might be new to this DSO stuff, or maybe just don’t use it a lot. |

Related AES Links:

• Peak and Hold Waveform Manual

• Waveform Reference Manual |

Back to Top

|

|

Tech Note 007:How to view alternator ripple

(diode patterns) with the Vantage® PGM.

Submitted by Brad Petersen

The Snap-on Vantage is a great tool with many

productivity enhancing features, such as, vehicle specific information and test setups.

One test setup not listed on the Vantage PGM is one for

testing alternators. Did you ever wonder why? Well, it is because the Vantage PGM does not

have AC Input Coupling and cannot process this signal in such a way to make it useful for

diagnosis.

AC Input Coupling filters out the DC (steady) portion of

a signal allowing only the AC (always changing) portion to appear on the display of the

test equipment. Many scopes (Fluke 98, Interro PDA, OTC Perception) provide AC Input

Coupling and can be used to test alternators with a set of regular test leads.

But, when you combine a special type of test lead and the

correct test setup with the Vantage PGM you can view the alternator ripple.

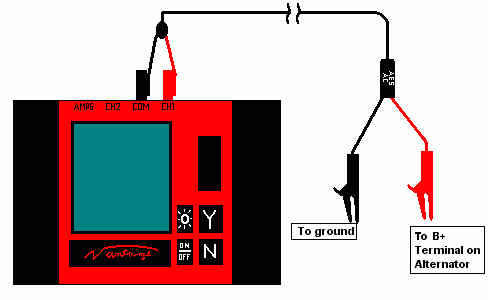

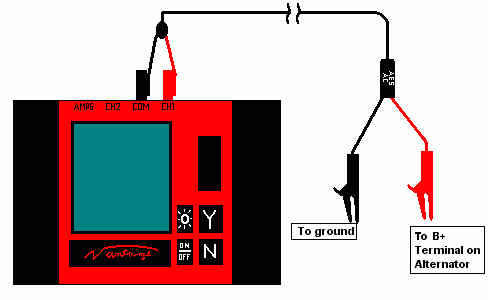

The example below illustrates how to setup the Vantage

PGM to test alternators with a special test lead that includes an in-line filter.

The test lead picks up the signal and delivers it to the

filter which blocks the DC (steady) portion of the signal and only allows the AC (always

changing) portion to reach the Vantage PGM and be displayed on the screen. Combined

with the correct setup on the Vantage PGM you will be able to view minor voltage changes

in the AC signal without regard to the DC portion of the signal.

This special test lead effectively provides AC Input

Coupling for the Vantage PGM and expands its testing capabilities.

Vantage Setup

The following is a pictorial sequence created by Brad

Petersen for using your Vantage PGM (Version 2 software) to look at the alternators

Brad created these graphics in MS Paintbrush, so some of

the images may not look exactly the same as the display on your Vantage.

Connecting the AES AC PASS FILTER

This is the setup used to check Alternator ripple (Diodes), using the AES AC Filter Test

Lead.

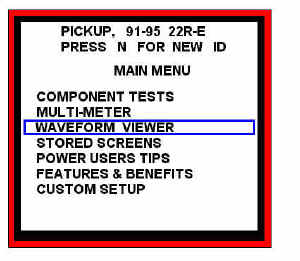

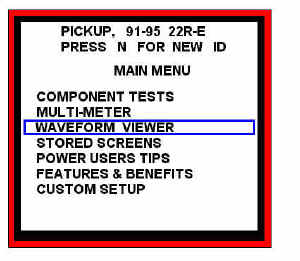

MAIN MENU SELECTION SCREEN

After hitting "N" after the first

power on screen, you should come to this screen. Scroll down and select Waveform Viewer.

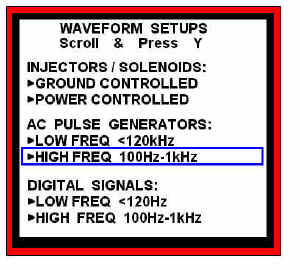

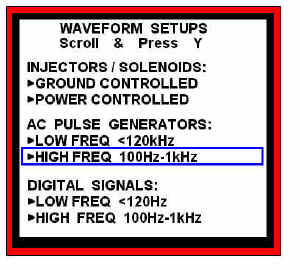

WAVEFORM SETUP SCREEN

After selecting Waveform Viewer, this menu comes up.

Select AC Pulse Generators, High Frequency, as shown.

HIGH FREQ SCREEN SETUP

After selecting AC Pulse generators, High Frequency, the waveform viewer defaults

to this screen. Scroll through and select the time base, hit "Y" and scroll to

change the time base from 100ms to 10ms. Then scroll each, to the Upper and Lower voltage

ranges, hit "Y" and scroll to change the voltages to +1 and -1 and hit

"Y" on each. This will set the Vantage to 10ms sample, within the ranges of +1

to -1 volts. The Vantage is now ready for viewing the Alternator ripple (Diode pattern).

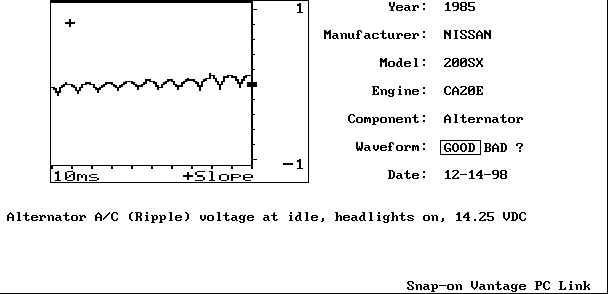

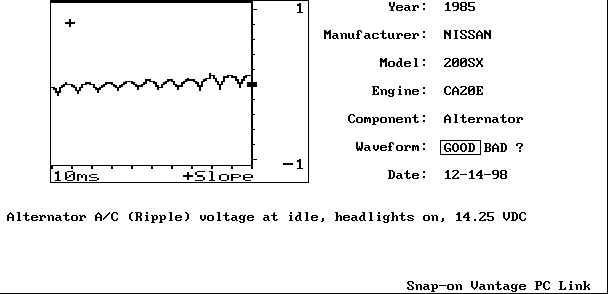

A GOOD SAMPLE WAVEFORM

Just a snap shot of a known good alternator as seen

by the Vantage. Note: Using waveform viewer in low frquency A/C pulse generator mode will

yield a good image of the diodes/ripple. AC Pass filtered lead set used, taken at

alternator B+ post.

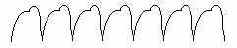

A HAND DRAWN SAMPLE OF BAD WAVEFORM

Would have been taken at the B+ lug on the back of

the Alternator, using the A/C pass filter, Vantage set on Waveform Viewer, A/C High

frequency.

Note: this was not an actual waveform, but a re-creation

done in paintbrush for simulation purposes.

Hope this helps.

Brad Petersen |

Back to Top

|

|

Tech Note 006:

Coil over Plug Ignition

1990 NISSAN 300ZX 3.0L NONE TURBO

Submitted by David Goldberg

The customer that owns this car drove in

complaining of stalling and hard starting after the engine got hot. The engine started and

ran fine stone cold. When it reached operating temperature, the engine would start

misfiring. Cooling the igniter down with a choke tester restored the ignition. After

replacing the igniter with an updated unit, the bad alternator diode was found.

The culprit is exposed:

|

Back to Top

|

|

Tech Note 005:

5 Critical Sensors for

Correct Engine Response

Submitted by Jerry Truglia

O2 SENSOR:

A. 0-1000mv=1 volt, range. Some sensors may go to 1.2 volts.

B. Some sensors are heated using system voltage. Be careful if you get a

high voltage reading on the signal line. This may occur if there is a problem in the

heater part of the sensor.

C. Renix systems use 5 volts to 0 volts (5volts lean, 0 volts rich).

D. Check with KOEO to see that you have approximately 450mv on a zirconium

sensor, 1volt or 5 volts on titania sensors. Use a Scanner, DVOM or Labscope to test the

sensor.

LOAD SENSOR:

A. Map Analog used by GM, Chrysler, Honda, Toyota and other Asian

manufactures as well as European manufactures.

B. Map Digital used by Ford.

C. Vane Air flow meter used by European, Asian and Domestic manufactures.

D. Hot Wire used by many manufactures.

E. Film Type used by Bosch and GM.

F. Honeycone type used by Mitsubishi.

TPS:

Variable resistor sensor that control fuel delivery by throttle

movement.

A. Check the sweep with a labscope to see if you have a drop out.

B. Any problem with this sensor can cause a hesitation or stumble.

C. Check this sensor in a no start conditions because of clear flood voltage

levels.

CTS / IAT: Coolant and Intake Air

Temperature sensors. A. Most of these sensors are the NTC negative temperature coefficient

type (high voltage and resistance cold, low hot). B. These sensors control fuel delivery

and are important for proper fuel delivery.

ENGINE SPEED:

A. AC Voltage type, most of the time two wires sensor although some will

have a third wire for shielding.

B. Hall Effect, a three wire sensor that uses power ground and signal which

produces a square wave.

C. Optical, uses four wires one power, ground, low data and high data rate

and produces two square waves.

D. All of these sensors control fuel and spark on today’s vehicles and

are used by the vehicle manufactures.

To test the above sensors you can use:

1. a scan tool to see if the computer is displaying rpm on the scan tool.

This will telling you a signal is being produced and getting to the computer.

2. a DVOM to check AC voltage or DC voltage on Hall and Optical, but this

will not be as accurate as using a labscope.

3. a labscope will give you a picture of what is really happening and the

ability to see small dropouts, you know a picture is worth a thousand words.

It’s a good idea to have a

software program to store waveforms to compare it to the signal that you have on your

scope from the vehicle. I recommend using the AESWAVE program, it’s easy to use and

communicates with most scopes and scan tools. Check it out, as Jorge would say, Catch the

WAVE.

AES Wave Note: Do the

following to save text into your AES Wave! database(s):

1. Select the text you want to copy by clicking and dragging your mouse over the

text you want.

2. If you are using MS IE you can right-click the mouse to select the COPY

command. You can also select the EDIT / COPY command from the menu. I assume

this method will work with the NetScape browser.

2. Open your AES Wave! database and click EDIT / PASTE on the menu bar. The text

should appear in a window.

3. Then click on the SAVE to DB icon and enter all the info you can.

NOTE: You use this same method to copy text from any other Windows program.

|

Related AES Links:

• Waveform Reference Manual

• Advanced Engine Performance

• JENDHAM

handbooks and Traning Manuals |

Back to Top

|

|

Tech Note 004:

Vacuum Waveform Case

Study

Submitted by Jack Dilger, Emissions Systems Inc

The Car:

1988 Honda Accord, 2.0 L 4 cylinder engine, 56,000 miles

The Problem:

Engine has slight "puff' at tailpipe and is due its 60,000 mile service.

Valve train is slightly noisy. Scope pattern shows slightly erratic secondary ignition

display and visual inspection of spark plugs show replacement is needed. Vacuum waveform

shows a different pattern consistently below cylinder #4 firing spike (see figure below).

Companion cylinder is determined to be cylinder #1. #1 is repeated

and verified by moving trigger clip ( ch 1 ) to cylinder #4 and going to single trace (see figure below).

Static compression test is performed to test cylinder sealing and

running compression test is performed to confirm cylinder breathing.

Results:

Static (cranking 3 puff )

1=160 2=165 3=160 4=145 PSI

running (scrader pushed in)1=100 2=80

3= 80 4=75 PSI

Problem has been located (using the vacuum waveform) and verified using the compression testing above.

Running compression should always be approx. 1/2 of cranking,

compression

The fact that #1 cylinder shows a higher than normal increase

proves that the vacuum waveform is correct in its pattern of a different pulse on this

cylinder. This vehicle needs a basic "tune-up" and a very much needed valve

adjustment.

We will advise the results of the valve adjustments at a later

date.

Click on the image to view

full size:

AES Wave Note: Do the following to

save images into your AES Wave! database(s):

1. If you are using MS IE you can right-click most any of image and select

COPY. I have not determined how to do this with NetScape.

2. Open your AES Wave! database and click EDIT / PASTE on the menu bar. The image

should appear in a window.

3. Then click on the SAVE to DB icon and enter all the info you can.

|

Related AES Links:

• Fluke Pressure & Vacuum

Transducer |

Back to Top

|

|

Tech Note 003:

Fuel Injector Signals

Submitted by Bill Lakow

Fuel injector signals have a few

different characteristic shapes. The majority of injectors are ground controlled. Voltage

is supplied to the injector when the ignition is on and the PCM controls the injector on

time by completing the circuit to ground.

There are a few manufacturers that turn the injector

on by supplying voltage through the PCM.

All of the waveforms (eight of them) presented below

are typical good signals.

Fig 1 Saturation Inj.

Fig 2 (below) Saturation Inj.

Fig 3 (below) Peak and

Frequency Modulated Hold

Fig 4 (below) Peak and

Frequency Modulated Hold (PNP Driver)

This injector is normally grounded and activated by supply voltage.

Fig 5 (below) Peak and frequency modulated hold, used on some GM throttle body

systems.

Fig 6

(below) displays the injector current and voltage traces

Fig 7

(below) displays the injector current and voltage traces

Fig 8

(below) displays the injector current and voltage traces

Helpful hint: Dynamic

testing with a milliamp current probe is faster and more accurate than static

testing with an ohmmeter. Use Ohm’s law to determine the proper current level. Adjust

the values for the number of injectors that are sharing each control circuit.

NOTE: Why are these waveforms

distorted? I do not know, I resized them to retain Aspect Ratio and they look fine

in my editing program. But when I see them online they become distorted. These were

sent to me embedded in a MS Word document and that could be part of the problem. If

you paste them into your AES Wave database(s) they should lose their distortion.

|

AES Wave Note:

Do the following to save these screen captures into your AES Wave!

database(s):

1. If you are using MS IE you can right-click any of the images

above and select COPY. I have not determined how to do this with NetScape.

2. Open your AES Wave! database and click EDIT / PASTE on the menu

bar. The image should appear in a window.

3. Then click on the SAVE to DB icon and enter all the info you

can. |

| Back to Top |

|

| Tech Note 002: Notes on AC Voltage

Submitted by Bill Lakow

Many lab scope signals may appear to be good

at a glance. However, your experience and closer examination of the trace will help to

evaluate the features of a trace that will lead to the cause of the problem.

Figure 1 and Fig.

2 are Ford PIP signals:

Figure 1 (Above) has noise

on the tops of the digital signals. The noise is caused by AC voltage riding on the DC

signal.

Figure 2 (below) is an

example of too much AC voltage that can interrupt the signal and cause a driveability

problem.

When AC noise is detected on a DC signal, test the

alternator ripple. With an Interro PDA, select the Diode Pattern test in the Engine Test

Menu and connect the current probe to either battery cable and record the ripple pattern.

With other scopes you need to enable AC input coupling.

With scopes and meters without AC input coupling you should use the AES AC Pass

Filter Test Lead, it filters the DC portion of the signal so you can view the AC

"always changing" portion.

Figure 3 and Fig. 4 are

Alternator Ripple patterns:

Figure 3 (Above) Bad

alternator ripple.

Figure 4 (below) Good

alternator ripple.

|

Related AES Links:

• AES AC

Pass Filter Test Lead

• Waveform Reference

Manual

•

Interro PDA Accessories

|

| Back to Top Tech Note Spacer |

|

| Tech Note 001: Jay Mathes

All Imported Auto, Ridgecrest, California

A 95 Kia Sephia came in with MIL on. (Only cust

complaint too.) P1523 which is a solenoid voltage below a threshold

(8.5V?). The customer felt that the diagnosis of a bad battery was out of line, so I

captured a simple waveform to show them (see Figure 1 below).

Figure 1

Static, KOEO, crank and start. It is clear that when

the batt voltage drops below 7V that this code is a given. Freeze frame showed cold,

0 MPH, and monitors were all pending indicating PCM reset. The car actually started

OK, although it was clear it cranked a bit slow.

Another use of a Fluke PV350 (or other pres/vac transducer)

is to have a cranking compression record of a vehicle. Easy to set up. I also

use this set-up without the schrader valve to see the three pulses on rotary engines (see Figure

2 below).

Figure 2

|

Jorge's Notes:

Jay ---- Great job! The waveform in Figure 1 and what you did with it is certainly one of

the key values of a lab scope: You used it to prove your diagnosis to the customer.

Showing them a DMM reading would not be the same!

This one also shows the value of

the record feature on the Vantage allowing you to scroll through the data to find the

important events!

Excellent vacuum waveform in Figure 2. This concept can go to the next step if you wish to identify the

cylinder/pulses. Use a trigger pickup on plug #1 to ID the pulses. The trigger pickup will

put out a spike every time #1 fires allowing you to ID and superimpose the events! Oh yes,

if #1 is firing which cylinder follows with an intake stroke?

Jorge

Related AES Links:

• Snap-on Vantage PGM

• Fluke PV-350

|

Back to Top

|

Fluke 192

2-cl with glitch capture and record

Demo-it |

|

Electrical Troubleshooting

ShopBook |

|

HV Glove Kit

Keep Safe!

|

|

Flatrater Diagnostics

GM case studies |

|

Waekon

Probes and more |

|

Test Leads

Give your scope

new life! |

|

|

|

|