|

Tech

Note 016:

Submitted

by Bill Lakow

Customer

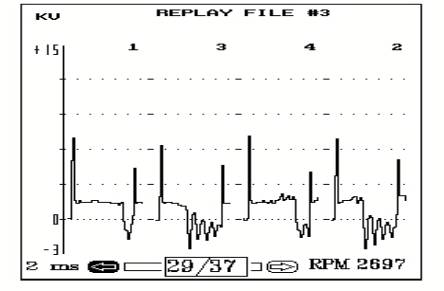

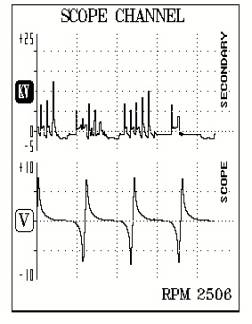

complains of a loss of power and bucking and surging. You connect your

scope and test the ignition system and discover four extra firing

events during a snap acceleration and you also notice that the firing

voltages are low (see Figure 1 below). The ignition wires, plugs and a

distributor cap appear to be recently installed. What could cause this

problem?

A A

The

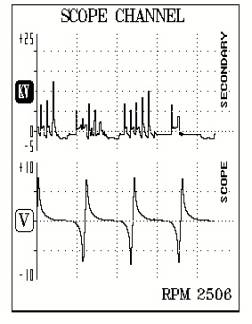

PDA provides the means to test the secondary ignition and the crank

reference signal at the same time. This test allows us to view the

relationship of the crank signal to the secondary ignition. To perform

this test, select ENGINE TEST

from the MAIN MENU and then

select SCOPE CHANNEL.

Connect a lab scope lead to the crank reference signal (see Figure 2

below).

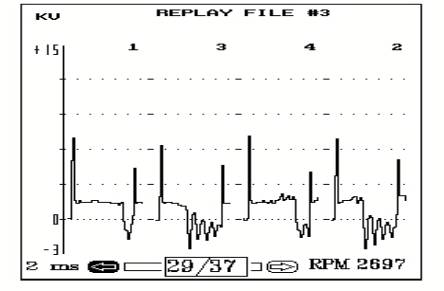

The

secondary pattern in figure 2 has more glitches during this test, but

the crank sensor signal appears to be good. The glitches in the

ignition are probably not caused by the crank sensor or the

distributor.

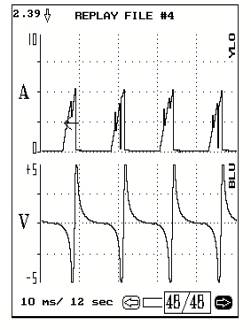

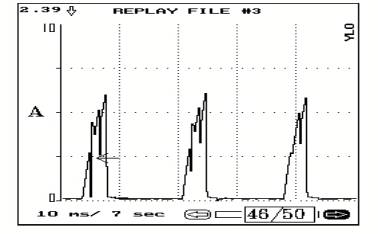

The

next test shows the relationship between the crank sensor and the

ignition module. Figure 3 (below) shows the ignition coil current on the top

and the crank sensor on the bottom. The problem is revealed in the

current waveform of the igniter. The igniter is failing to maintain

the dwell period and each time the ground fails to hold the dwell, the

field collapses and a premature firing event occurs.

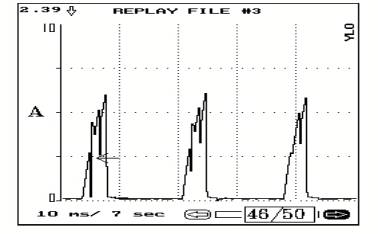

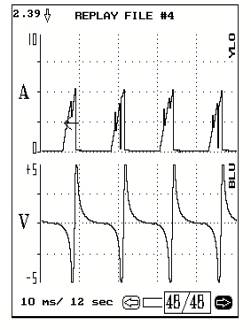

Figure

4 (below) shows a more detailed look at the coil current flow. Each

downward sloping line indicates a break in the continuity of the

current flow, an open circuit. Every time the circuit opens the

primary field collapses prematurely.

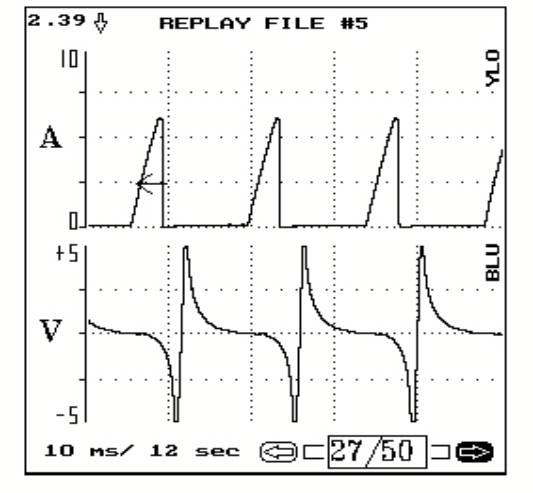

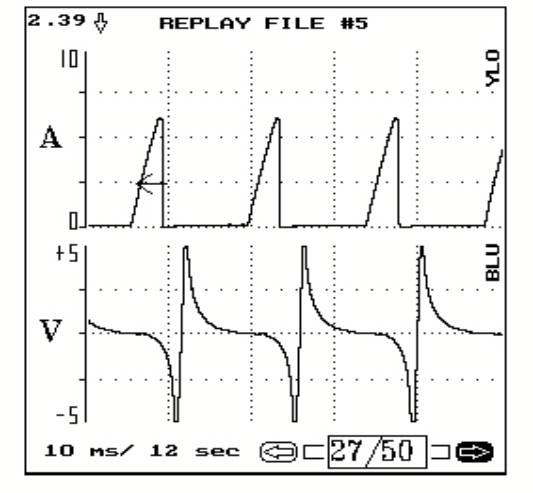

The

defective ignition module was replaced and figure 5 (below) shows a

good coil current trace over a good crank reference signal. Notice

that the current ramps, the angles of the signals, are uniform in

shape and show no dropouts in the signal.

The Milliamp Current Probe helped to quickly and accurately

diagnose this problem.

|